Imagine you are driving your brand-new mini-van, the latest Drake album cranked on high, the windshield wipers at top tempo, and the heater keeping things toasty. You go to switch the headlights to high-beam—and you are suddenly hit by the unmistakable odour of melting circuits….

Not a happy situation. It’s one that automotive designers the world over try to avoid by extensive testing of many different usage scenarios.

Problem-solving tools have dramatically changed the way engineers advance their knowledge, for financial, automotive, chemical, and other sectors. Many products and technologies we take for granted—such as the electronic circuitry in a mini-van—would not have seen the light of day without such math-based technical tools.

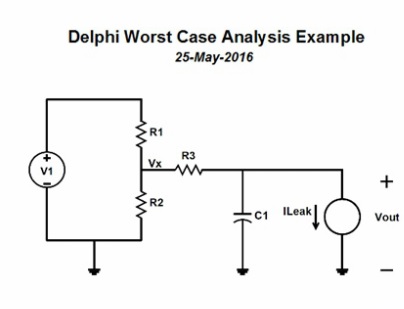

“Extreme value analysis is important for drawing attention to the problem areas in a design,” said Pratik Sheth, Technical Lead at the automotive firm Delphi. He was the third speaker in a webinar about symbolic computing held on May 25, 2016, titled “How Far Can Your Math Knowledge Go?”

“Extreme value analysis is important for drawing attention to the problem areas in a design,” said Pratik Sheth, Technical Lead at the automotive firm Delphi. He was the third speaker in a webinar about symbolic computing held on May 25, 2016, titled “How Far Can Your Math Knowledge Go?”

To test their designs, the automotive design team carries out Monte Carlo analyses, in addition to extreme value analysis. Each Monte Carlo analysis uses the system equations as well as information about the statistical distributions of the parameter values for each component.

Sheth summarized the instructions for carrying out the analysis of an electrical circuit in a vehicle:

- Begin with the image of the circuit.

- Choose what analysis and what settings you want to simulate.

- Import Netlist, which contains detailed information about each electrical component used in the circuit.

- Check the table of minimum, normal, and maximum values for parameters related to each electrical component.

- Generate the system equations using the symbolic computing software (in this case, Maple).

- Generate code from the equations (also handled by the symbolic computing software).

- Run the desired analysis.

“The output is then used to look at tolerance limits,” Sheth said, and any problem components can be identified for further study and development.

Symbolic computing is an integral part to understanding the real-life stresses on sophisticated electrical designs. ª

Click here to read about the first presentation in the webinar (symbolic computing).

Click here to read about the second presentation in this webinar (automotive worst case analysis).